|

Established in 1971, WATERWORKS YUJIN(www.yujin21.com) is in the business of manufacturing faucets (kitchen and bathroom faucets). Although faucets and showerheads come installed in apartments, the water pressure varies from floor to floor. WATERWORKS YUJIN’s water pressure control technology is a part of their unique know-how based on years of experience, and because they manufacture and sell their products directly, after service (AS) is readily available. Recently, the company developed the world’s first water-saving faucet “Eco-Step,” which can control water pressure. With the patented cartridge, water saving and temperature adjustment functions can be carried out in increments.

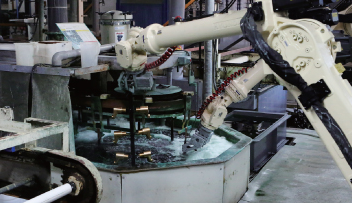

On the face of it, WATERWORKS YUJIN and robots seem completely unrelated. WATERWORKS YUJIN Co., Ltd. drew attention from the robot industry in 1993 when they introduced robots to the polishing process. Through a project with the Korea Institute of Science and Technology, the company used robots to carry out work on curved surfaces or difficult shapes, which was beyond the conventional one-dimensional automatic polishing. At the time, the project to use robots in the polishing process at the faucet manufacturing site became an issue in the robotics industry.

In 2008, in order to reduce the cost of production, they company developed a work robot to polish the surfaces of the faucets; in that year, they installed six polishing robots at their Hwaseong factory in Gyeonggi Province, saving 300 million won every year.

WATERWORKS YUJIN was compelled to enter the robot business because of the 3Ds of the industry. Although root industries such as casting, plating and polishing form the foundations of the industry, the work itself is generally regarded as being a “3D” type of business, resulting in a severe manpower shortage. Because of poor working conditions during the manufacturing process, the need to handle harmful chemicals, and shifts that often need to be divided between 24 hours a day, WATERWORKS YUJIN made the decision to dive into the industry to make their own robots for these tasks.

In addition to polishing robots, since 2010 the company has been working to develop and sell robots for use in other industries such as plating and ablation. A company associate remarked, "Going forward, it will become harder to hire people in the root industry. Unlike now, where the casting, plating and polishing is done all at one factory, these tasks will be broken down and specialized.” As the next generation growth engine, the company indicated they would double down on their efforts in this industry.

| |

|

|

| ▲Robot Automation Project for Chemical Polishing of Metals |

Last year, WATERWORKS YUJIN undertook the “Robot Automation Project for Chemical Polishing of Metals,” a project carried out by the Korea Institute for Robot Industry Advancement to support innovation in small and medium manufacturing processes using robots. This project had the objective of automating the metal chemical polishing process for the cosmetic container manufacturer, YONWOO. Because the chemicals nitric acid, sulfuric acid, and phosphoric acid need to be dealt with, the process itself is dangerous. However, since the polishing work is repeatedly performed at high temperatures, there have been cases of workers in this field being diagnosed with musculoskeletal diseases. As such, this field of work is considered to be an archetypal 3D occupation.

| |

|

|

| ▲ Plating Process |

The project was a way for the company to overcome these issues with robots. Upon robotization at the company’s factories, two workers are now doing work that once required seven workers. Moreover, productivity has increased in excess of 50%. A 4000 unit output per hour has increased to 6300 units per hour, an increase of 58%, and the defect rate has fallen drastically from 2.7% to 0.12%. With automation, the delivery rate compliance is at 99.5%, an improvement of more than 3%. More importantly, the industrial accident rate fell from 2.8% to zero. On the heels of these successes, last year, WATERWORKS YUJIN was selected as an Excellent Supervisory Company by the Korea Institute for Robot Industry Advancement.

| |

|

|

| ▲ Polishing Process |

| |

|

|

| ▲Ablation process |

It was evaluated that by supplying Korea lostwax Co. Ltd with an automated cast iron cutting system and JUNGHWA TECH Co. Ltd. with an automated door lock polishing system, WATERWORKS YUJIN Co., Ltd is reaching new potential by putting robots to work on site, rather than simply using them for transfer or assembling. In particular, industrial accidents are quite frequent during work hours at the cast iron cutting site, so bringing in robots has resulted in high production efficiency as well as lowering industrial accidents. The automated door lock polishing robot has also increased output and precision. In the case of polishing work, there was increased satisfaction in introducing robots directly to the faucet polishing site.

|